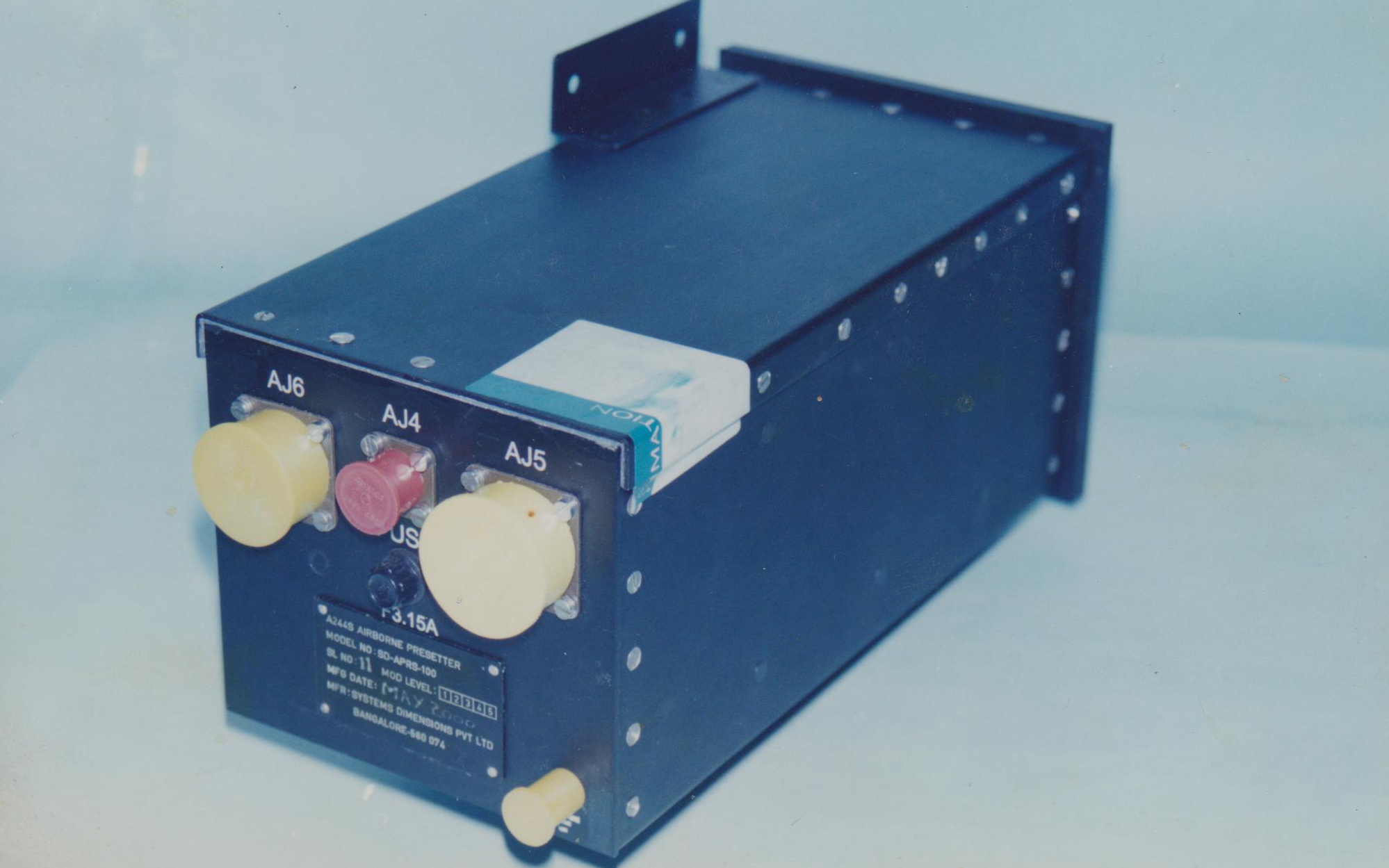

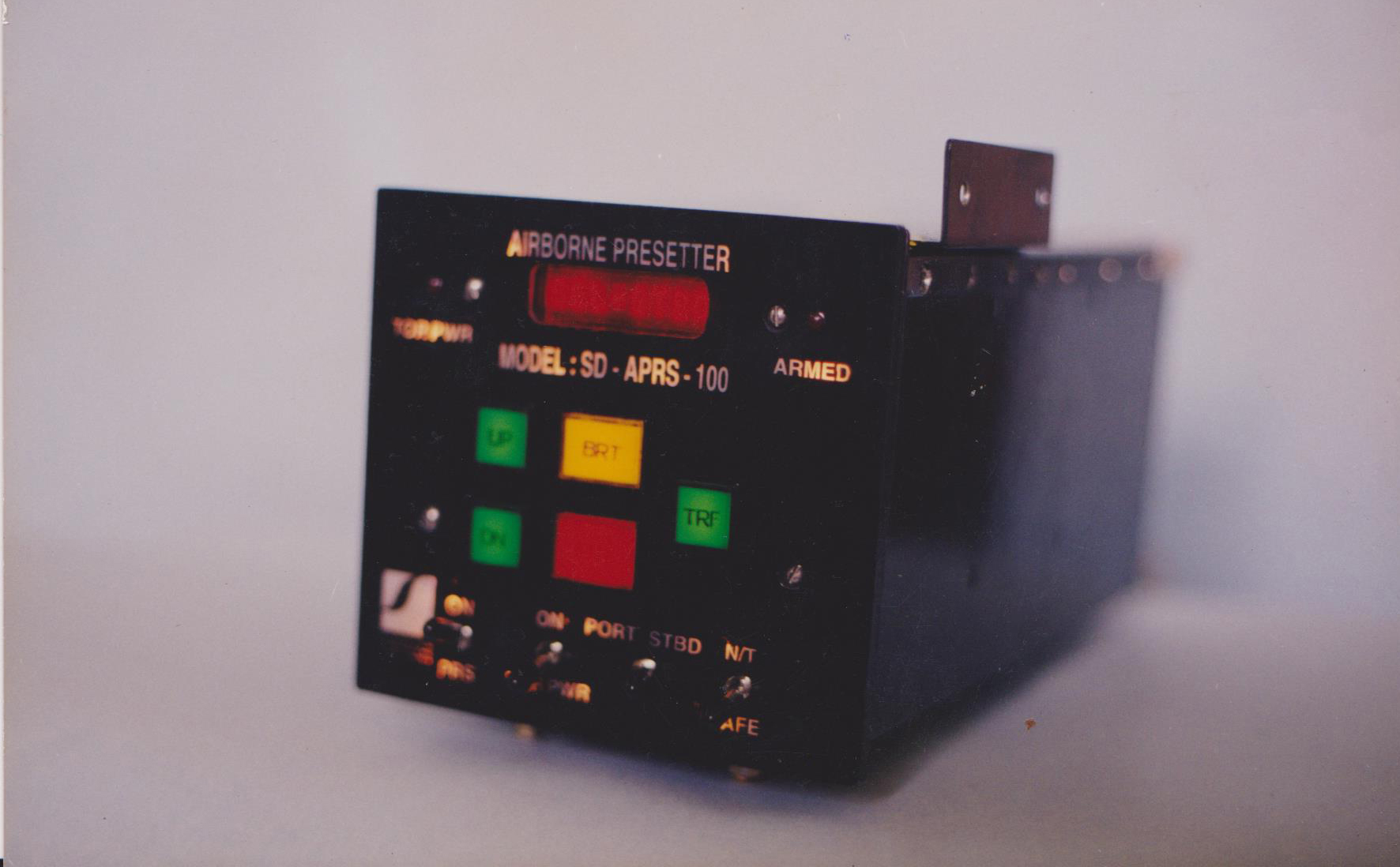

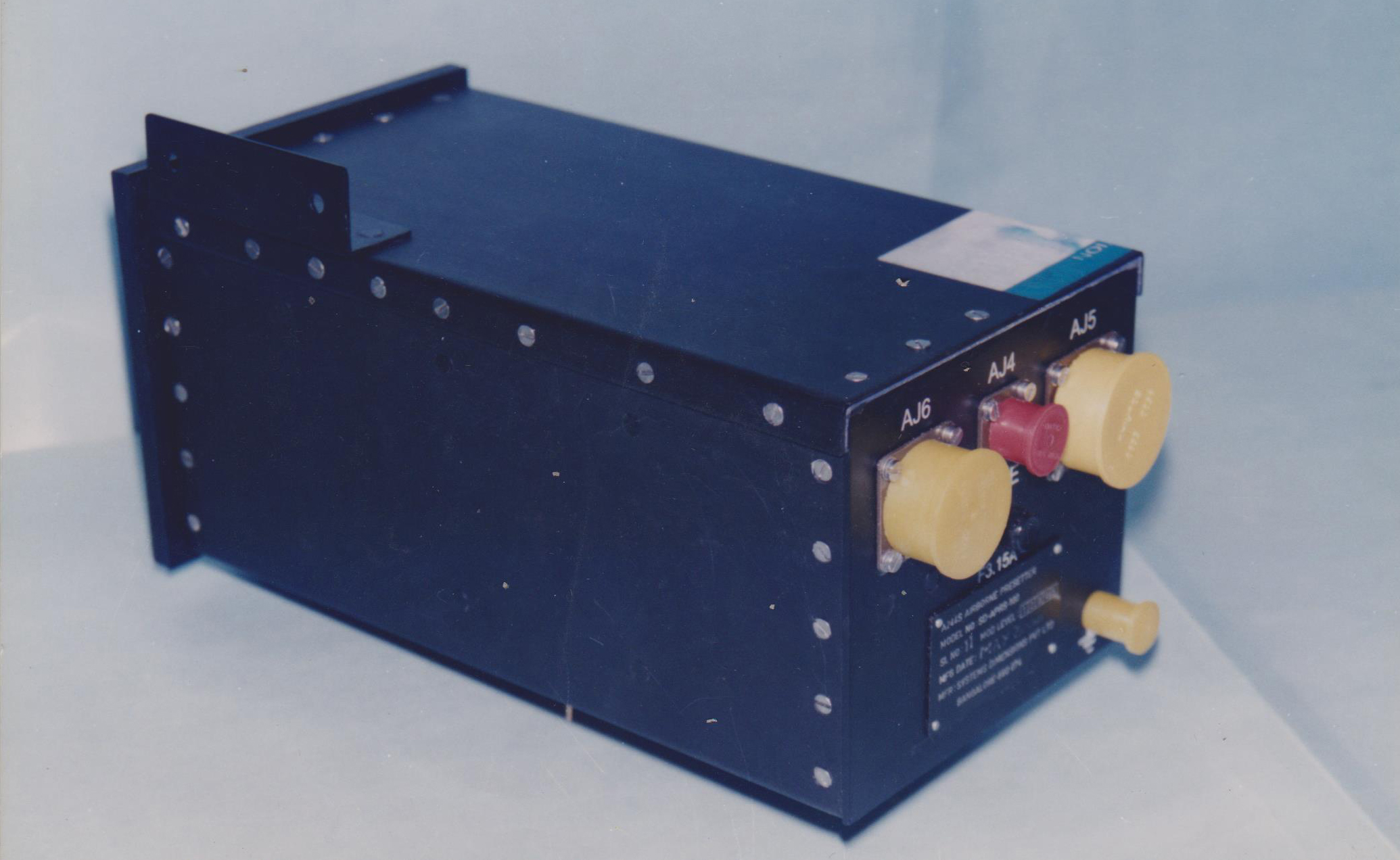

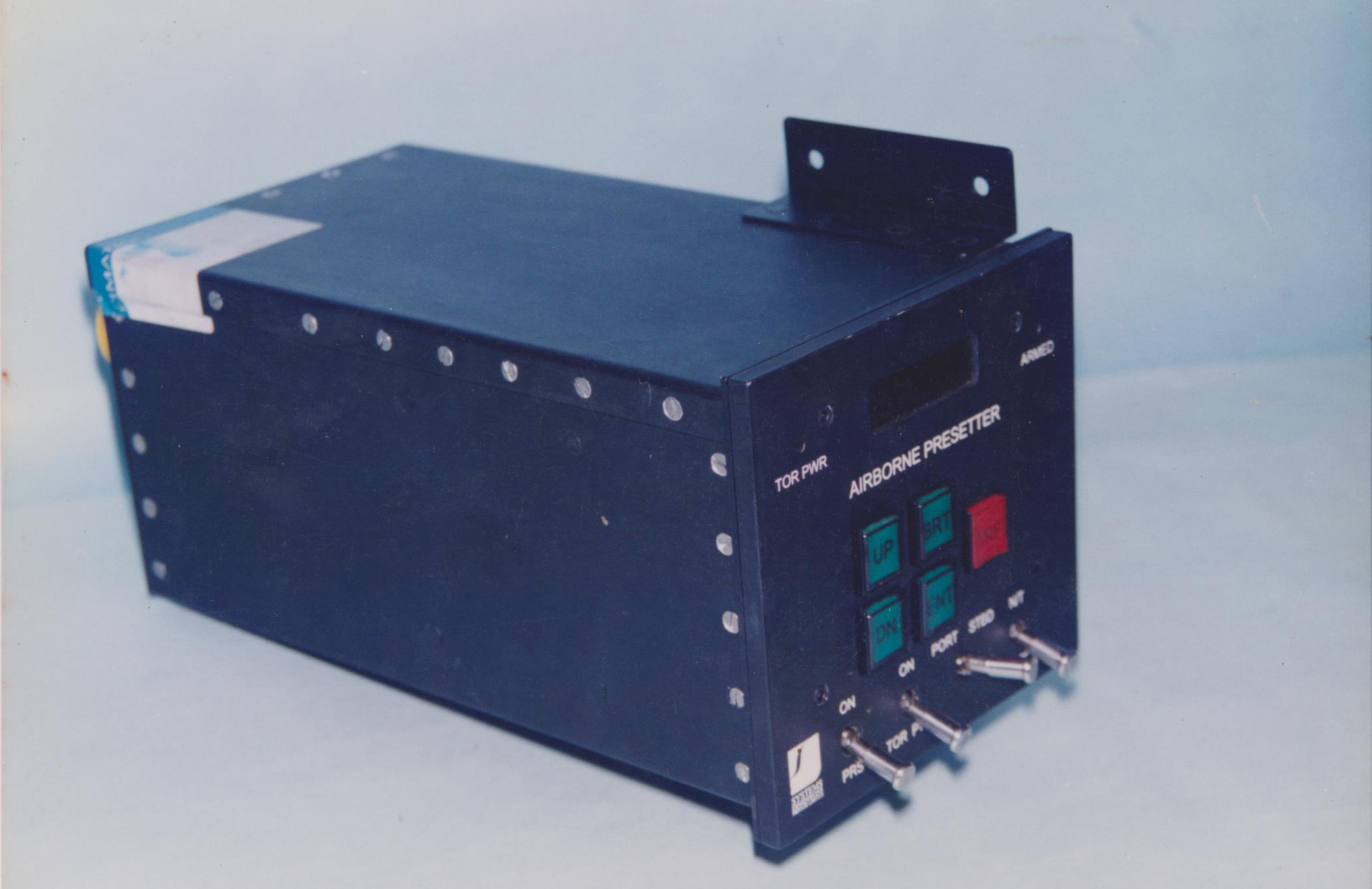

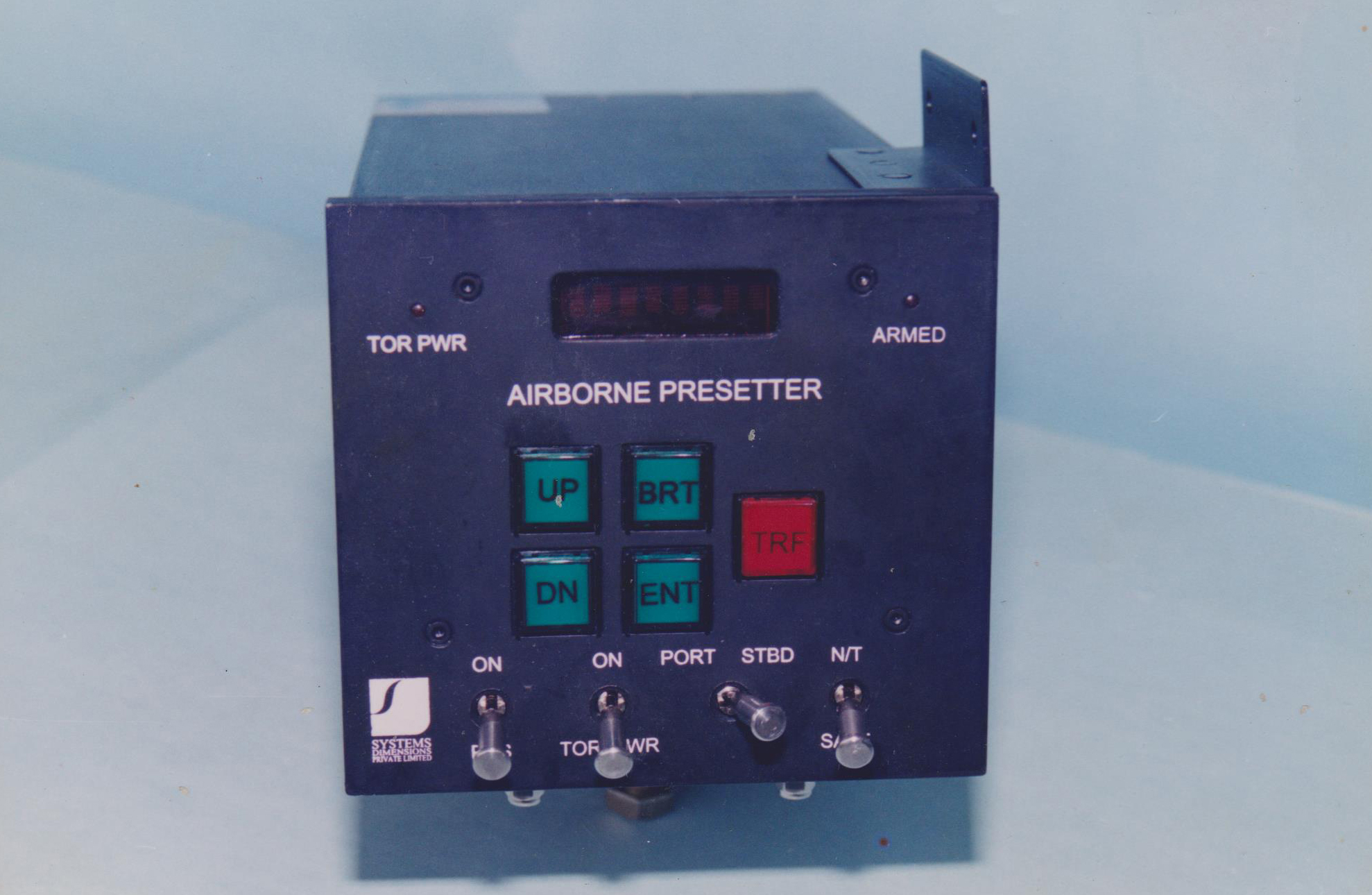

The TAL/A244S Torpedo Airborne Presetter is designed to install on chetak /ALH(Advance Light Weight Helicopter) helicopter. The TAL/ A244S Torpedos are electrically propelled light weight Torpedos for operating against submarines in shallow and deep waters.This incorporates a homing head , capable of active,passive or mixed modes for closing onto the target.

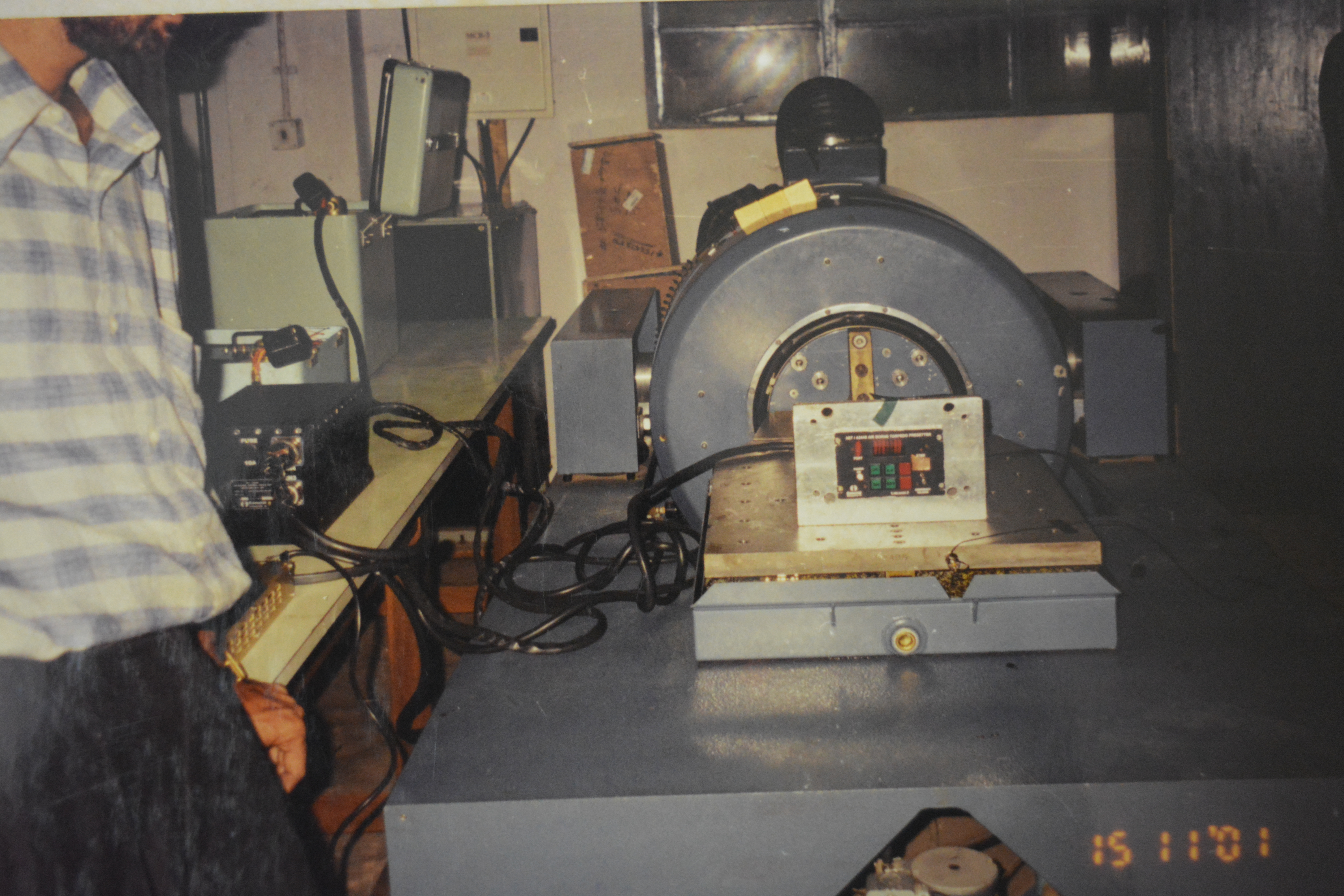

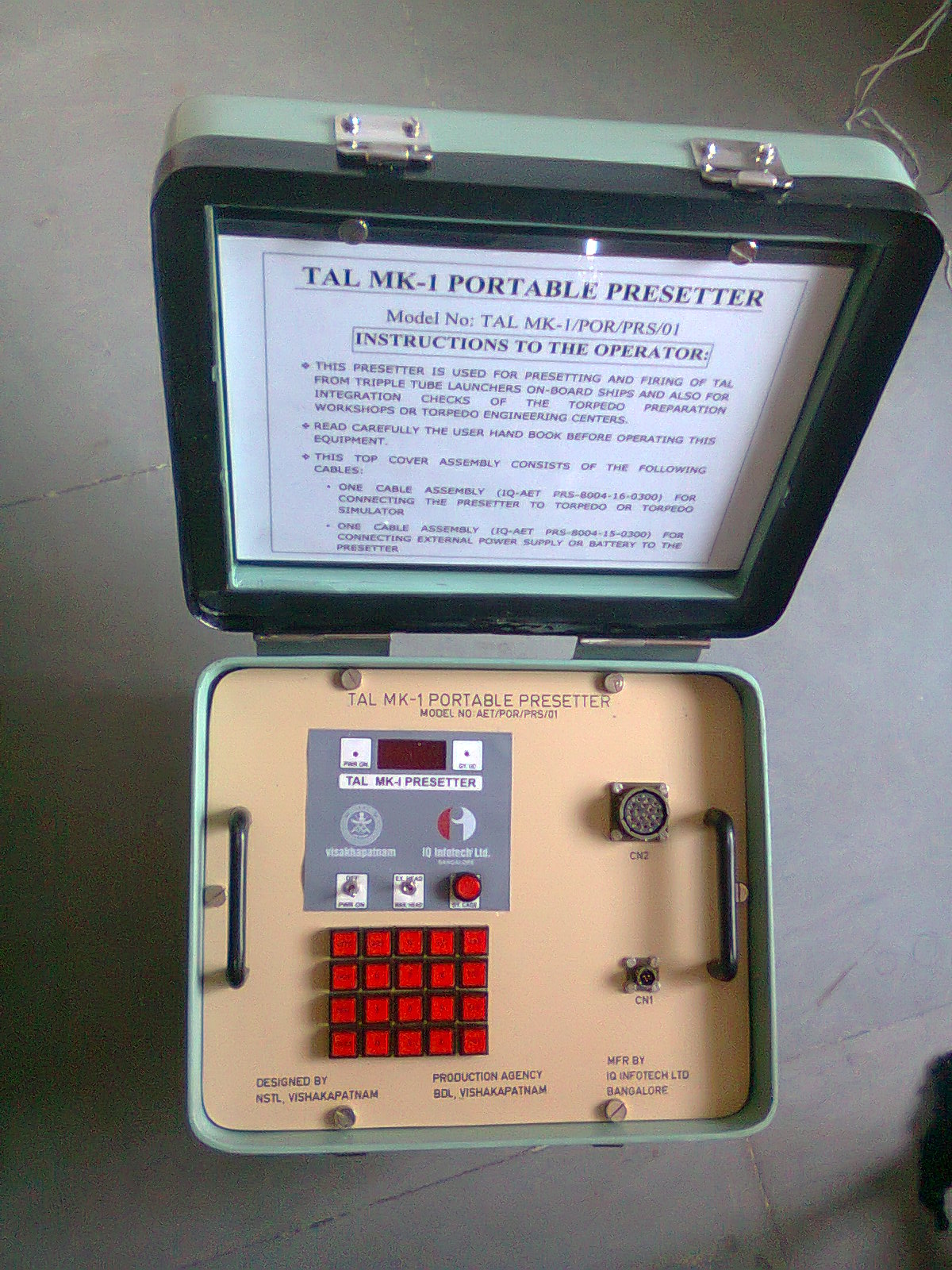

The Torpedo simulator is used for testing TAL Mk-1 Portable Presetter by simulating TAL to ensure the serviceability of Presetter before connecting to the actual torpedo. It is also used by operators for presetting the TAL. The TAL MK-1 simulator is connected electrically to the Presetter through a cable assembly.

This unit is used to preset the parameters, Monitor and Display the status of subsystem of the TAL Torpedo prior to its launch. Tal-Mk-1 Portable Presetter is used for integration checks during the preparation of torpedo for Launching.

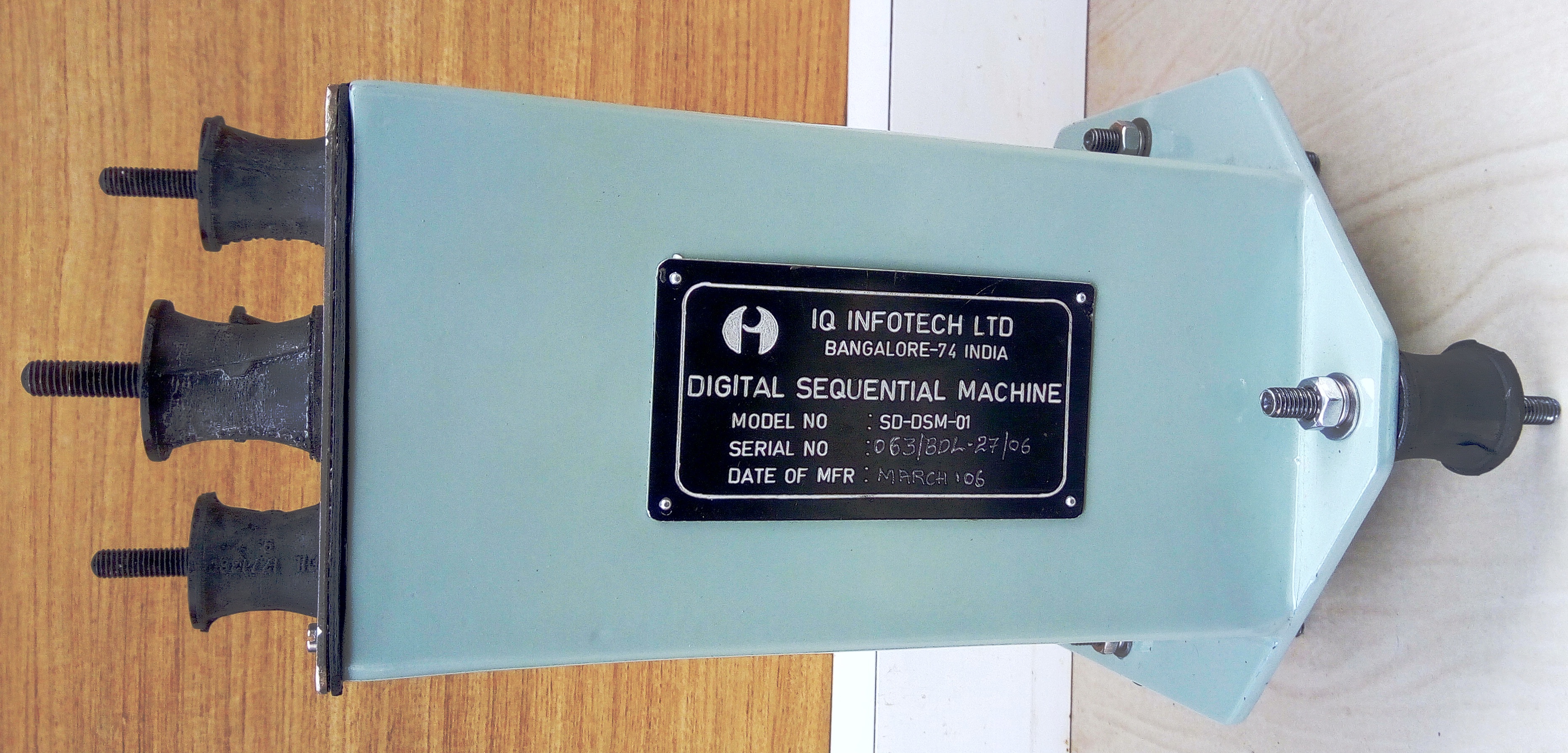

The digital sequential machine is tested using Portable Presetter or TAL/ A244S Torpedo Airborne Presetter by simulating the TAL TORPEDO to ensure the serviceability before mounting inside the DRILL & PRACTICE (D&P) TORPEDO.

The DIGITAL SEQUENTIAL MACHINE (DSM) is fitted inside the A244S TORPEDO. Operators use the A244S Torpedo for training i.e. Drill and Practice firing from Ship or Helicopter. The A244S Electronic unit is used for simulating the A244S Torpedo. The A244S DSM D&P Electronic unit functionality can be ensured by using the Portable Presetter or TAL/ A244S Torpedo Airborne Presetter. The digital sequential machine is tested using Portable Presetter or TAL/ A244S Torpedo Airborne Presetter by simulating the A244S TORPEDO to ensure the serviceability before mounting inside the DRILL & PRACTICE (D&P) TORPEDO.

The undercarriage/slat/flap Position indicator is an instrument fitted in the cockpit of Jaguar aircraft and provides vital information for the undercarriage/slat/flap position. The function of slat and flap is indicated through LED’S on the top of the front panel and undercarriage position is indicated through LED’S on the bottom of the front panel. Operation of the flap is indicated through a digital bar graph display indicating the position of flaps 0° - 40°.

The Thermocouple conditioning unit is completely analogue circuit that provides analogue voltage, which represents the engine turbine gas temperatures to the data acquisition system. The unit accepts signals from two ‘K’ type (Chromel/Alumel) thermocouples and provides independent output voltage in the range of 0 to 10v representing the temperature range 0 to 1000°C, which are fed into DAU for processing.